Healthcare labels are used across various facilities in the healthcare industry. They are used in hospitals , clinics and pharmacies for everything from patient identification to test tubes. Labels must be durable to withstand various environmental conditions and be versatile for easy application on a range of surfaces.

You can find many different types of labels, but there are some healthcare label materials that are going to be ideal for the healthcare and pharmaceutical industry . This guide will provide helpful information on selecting healthcare label materials that are best suited to your practice and facility.

Healthcare labels have various functions and purposes in the medical industry. They can be used to display information such as:

Names and identification numbers

Barcodes and QR codes

Clear usage and instructions

Critical patient information

Product specifications

Expiration dates

Storage and transit information

Dosage and ingredients

Names of facilities, departments or hospitals

Warnings

When selecting healthcare label materials, you must ensure they meet quality standards and requirements.

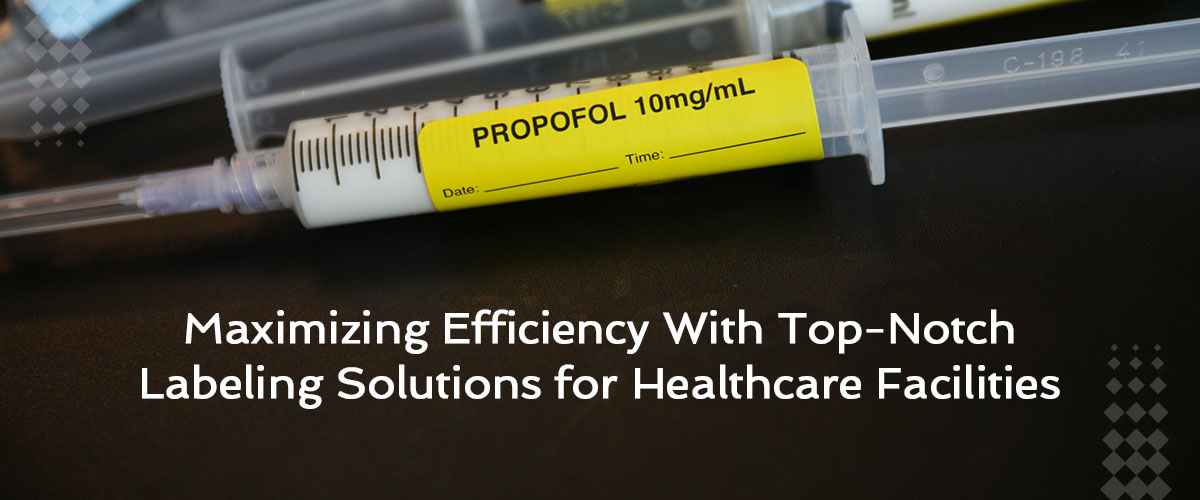

The information on healthcare labels must be readable and clear. Healthcare product label materials are often white or clear to ensure the text is easy to read and follow. For small containers such as vials , test tubes and syringes, you must ensure the text is large enough to read. The text, barcode and design must be legible even after various environmental conditions.

Consider the container you will place the label on when selecting healthcare label materials. Some containers are small, such as ampoules, and others are large, such as corrugated boxes. A flat surface allows for an easy application, and it limits the risk of the labels lifting at the edges. Small round containers such as bottles and test tubes might curve at the top, however, making it crucial to have the right materials and sizes for proper label application.

Label adhesive is made of acrylic or rubber. In healthcare, acrylic is often used. There are various types of label adhesives including permanent and removable. As the names suggest, permanent is long-lasting, and removable allows you to separate the label from the container easily. Removable labels do not leave behind residue, leaving the surface clean. The adhesion you use must also be suitable for your container surfaces.

Healthcare product label materials must be resistant to various environmental conditions. Non-durable labels can fade, tear and make information hard to read. When selecting a material, you must consider the conditions it will be used in. Will it be exposed to a hot and humid atmosphere or be in close contact with corrosive acids? To choose the best materials for healthcare labels, you must ensure they are:

Water-resistant

Heat-resistant

Smudge-resistant

Solvent and chemical-resistant

Alcohol and xylene-resistant

Dissolveable

UV-resistant

Abrasion-resistant

Resistant to bright lights

Resistant to cold temperatures

Healthcare labels are composed of several different components:

Facestock: This is the material you will use to print the information on.

Top coat: This is the top protective layer made of laminate. A top coat is optional in some healthcare labels as the facestock is typically made of durable material. If the facestock is made of non-durable material like paper, though, then you should use a top coat.

Adhesive: The adhesive is the sticky glue-like substance on the back of the facestock.

Liner: The liner is the material that the adhesive side is applied to. It is often made of coated paper or film which makes it easy to remove from the adhesive side.

There are many different surfaces on which healthcare labels are placed. Different containers, devices and storage are made up of different materials and components. When looking at the options for healthcare label materials, you must consider whether the adhesive will stick or remove under various conditions. Here are some of the surfaces that labels may need to be applied to:

Test tubes

Blood bags

Vials

Charts

I.V. bags and tubing

Storage boxes

Medical devices

To help you choose healthcare label materials for your practice, here are some of the best-suited label materials to use:

Polyethylene (PE): This material is highly water resistant. You can use this on medical equipment that contains fluids.

Cryogenic: This material works well in cold and freezing environments such as pharmaceutical refrigerators.

Polyester (PET): Polyester is durable and resistant to heat, moisture and chemicals.

Top coated direct thermal: Direct thermal labels might not be durable. However, they become more durable when a top coat is applied to the facestock.

Tamper evident: This label ensures no one opens your packaging. If the seal is broken, then it is easy to identify.

Mylar: Mylar is resistant to chemicals and durable enough to withstand various environmental conditions.

The environmental conditions can affect label materials for healthcare packaging. If the atmosphere is humid, it can create moisture that affects the adhesion of the label. Moisture and grease can also smudge the ink which can make it difficult to read the label. Here are a few environmental conditions to consider when selecting your healthcare label materials:

Sterilization: While sterilization methods clean medical equipment, they can strip the label from them. Machines like an autoclave use steam and high heat that can affect the label.

Pharmaceutical refrigerators: Medical vials, ampoules and tubes are often kept in pharmaceutical refrigerators. The cold air can create moisture and lift the label. You should consider a cryogenic adhesive label that can withstand cooler temperatures.

Chemicals: Some chemicals, acids and solvents can cause ink on labels to smudge and deteriorate.

Shipment: When medical equipment is transported from one location to another, consider the rapid changes in temperatures that can affect the adhesion. It should also be durable to withstand wear from handling the equipment.

Use our hospital label material guide to help you select the most suitable labels. Nev's Ink supplies high-quality healthcare labels for all your medical needs and exceeds industry standards. We create made-to-order labels according to your requirements and specifications to provide a custom product fit for you.

Get in touch with our experts by completing an online contact form today. We will get back to you soon.